Add to Cart

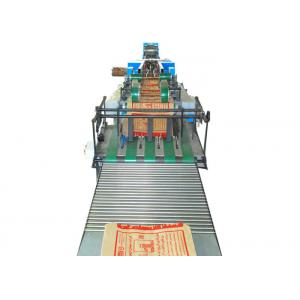

Energy Conservation Valve Paper Bag Making Machinery with Servo System

Brief Introduction:

Foshan Tecon Package Machinery CO., LTD is a high tech equipment manufacturer. We designed the first production line for paper bag 20 years ago, that's is about 1996, and now we are listed in the world top three in this industry and the only one in China able to design & manufacture the whole production line of bottom sealed paper bag.

Perfect service:

1. Technical consultation

2. Detailed design of factory or workshop

3. Project evaluation

3. Training engineers and workers

4. Supplying spare part for long time

5. Installing and testing the whole production line

6. Good after-sale and in-sale servcie

Features of our full-automatic paper bag production line:

1. Flat & glued bottom with filling valve;

2. Different types for cement, chemicals, foods, tea, etc.

3. 4-color automatic printing

4. 2~4 paper layers, with one extra PE/PP film available

5. 35~50 million bags/year

6. Servo system control or PLC control available, integrated with Photoelectric & Pneumatic control system7. Full technical service for installation, training and maintenance

8. Full solution for factory construction and materials purchase.

Technical parameters of our production line:

HD4913 Bottomer Machine

Operating condition

| Working hour | 22 hours/day |

| Design temperature | 0~40℃ |

| Design humidity | MAX. 95% |

| Number required | 1 unit |

| Model name | HD4913 |

Performance

| Speed | 80~130 bags/min(Depends on paper quality, number of ply and operators’ skill.) |

| Bag length | 520~880mm |

| Bag width | 420~600 mm |

| Bottom width | 90~130mm |

| Bottom open width | 200~380mm |

| Distance between bottom centers | 420~780mm |

| Valve sheet length | 100~250mm |

| Valve sheet width | 120~170mm |

| Main drive motor | 33kw |

| Total weight | 22.7T |

| Size of whole set | 21.3m×2.3.m×1.8m ( L×W×H) |

| Valve sheet reel diameter | Max.1,300mm |

Composing of the production line

HD4913 Bottomer Machine

| Name | Quantity |

| High speed feeder machine | 1 |

| Perforation machine | 1 |

| Tube opening unit | 1 |

| Automatic gluing machine | 1 |

| Scrip sealing machine | 1 |

| Bag bottom turning unit | 1 |

| Counting and delivery line | 1 |

| Automatic delivering out unit | 1 |

| Piling up platform | 1 |

| Electric control unit | 1 (Schneider, German) |

| Vacuum-pump | 1 (Schneider, German) |

After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we Strongly feels about the importance of supporting our customers and the product solutions we provide. Also we offer one year guarantee period, paid service for whole life.

Our machine:

Automatic valve paper bag machine for cement,chemicals and food